New equipment is being mastered

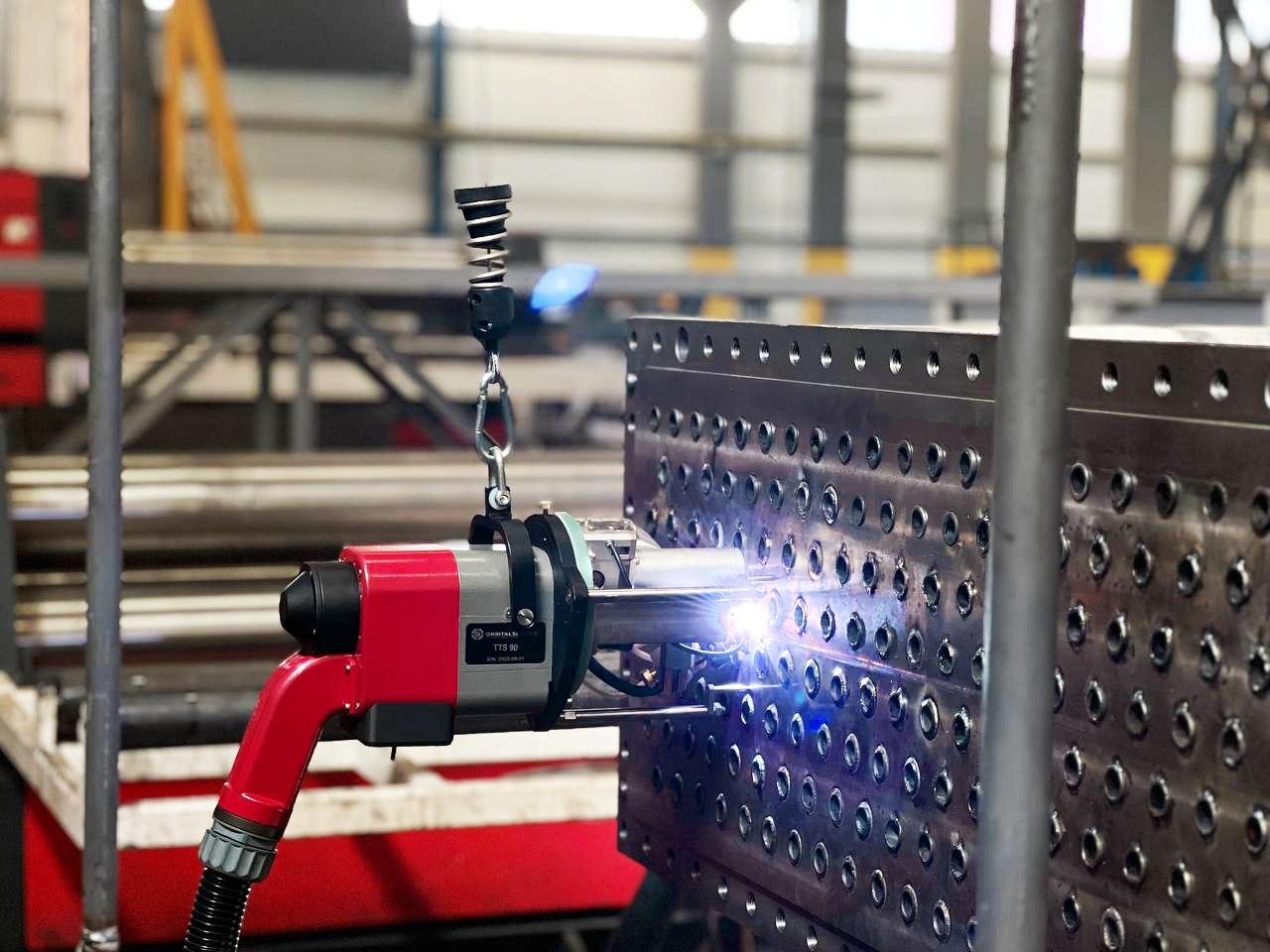

Machine-building plant of FDI "Enter Steel" LLC systematically expands the range of manufactured products. This is facilitated by strengthening of material and technical base of the enterprise, in particular, acquisition of new technological equipment. Thus, recently a new welding set for joining pipes with pipe boards of heat-exchange equipment manufactured by OrbitalServise and Lorch (Germany) was received.

⠀

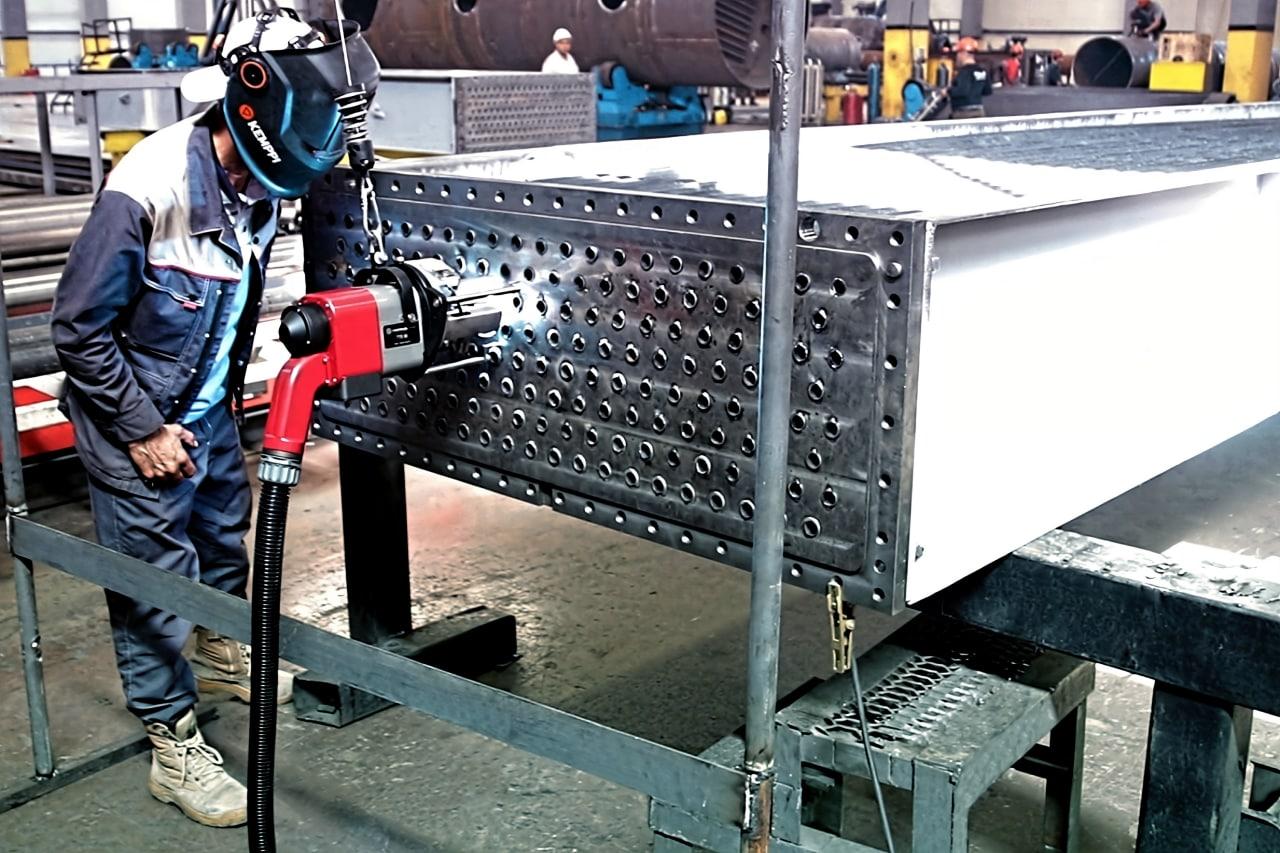

- This device is designed for welding thin- and thick-walled pipes into tube boards during installation or repair of heat exchangers," says Bekir Aliyev, chief welder at Enter Steel. - Precise alignment of the welding head in the pipe by internal diameter ensures high-quality welding of hard-to-reach areas of structures, which are under the greatest stress during operation, and increases its speed. This is a specific equipment and at the moment it is the only one in Uzbekistan.

Its purchase was planned back in 2020, but it could not be realised due to the pandemic. Finally, the first set was purchased in March this year, and the second is expected to arrive soon. According to Bekir Ismetovich, the welding machine was supplied by «Fin Weld Azia» LLP, which is the official representative of Orbitalservice (Germany) in the Republic of Kazakhstan and Central Asia.

Now Enter Steel has an opportunity to produce heat-exchange equipment and sections of air-cooling apparatuses (ACE). An important issue is also training of specialists who will have to work with this welding set. - We have identified the most experienced masters to work on the equipment we have received," Bekir Aliyev continued. - Now they are studying its characteristics, principle and technique of welding, acquiring necessary skills and abilities. To summarise, it should be noted that Enter Steel is already receiving orders for OrbitalServise and Lorch welding sets. комплект OrbitalServise и Lorch.